In a future shaped by engineering, Hot Makina will continue to make a strong name for itself in applicability, prototype development and mass production!

Hot Makina meticulously considers the production capacity, machine capabilities and manufacturability analysis of the parts during the detailed evaluation process on your requests. Hot Makina aims to provide effective and cost-effective solutions in production processes, to establish long-term business relationships with our customers by committing to quality production and timely delivery by making detailed examinations of your proposal requests and projects.

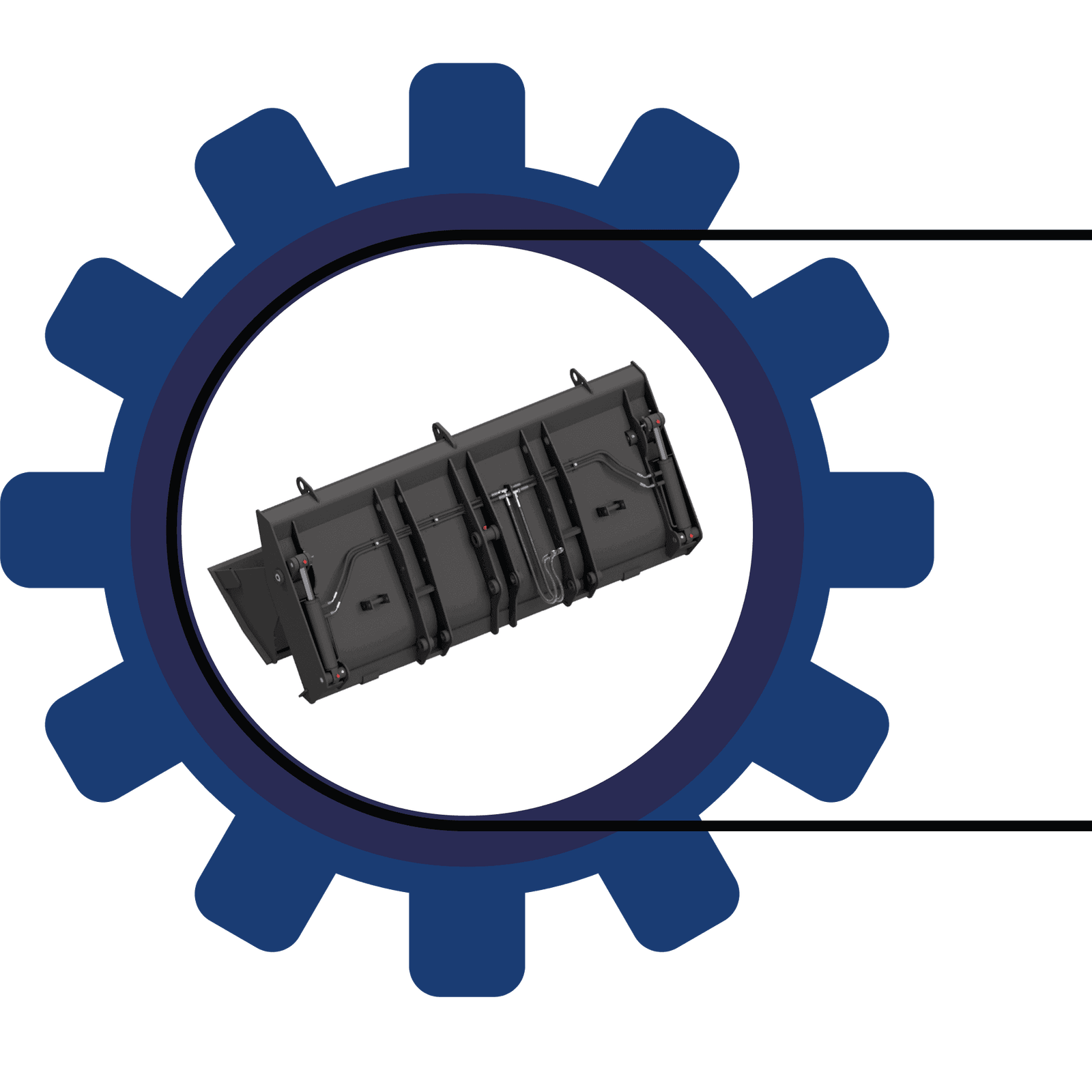

Our design team uses the latest 2D and 3D design tools to bring fixture, jig, jig and gauge designs to life with a customized perspective. They also use advanced methods such as simulation and tolerance analysis to ensure that each part is manufactured with perfect fit and quality. This approach allows us to speed up our processes and create solutions tailored to our customers’ demands.

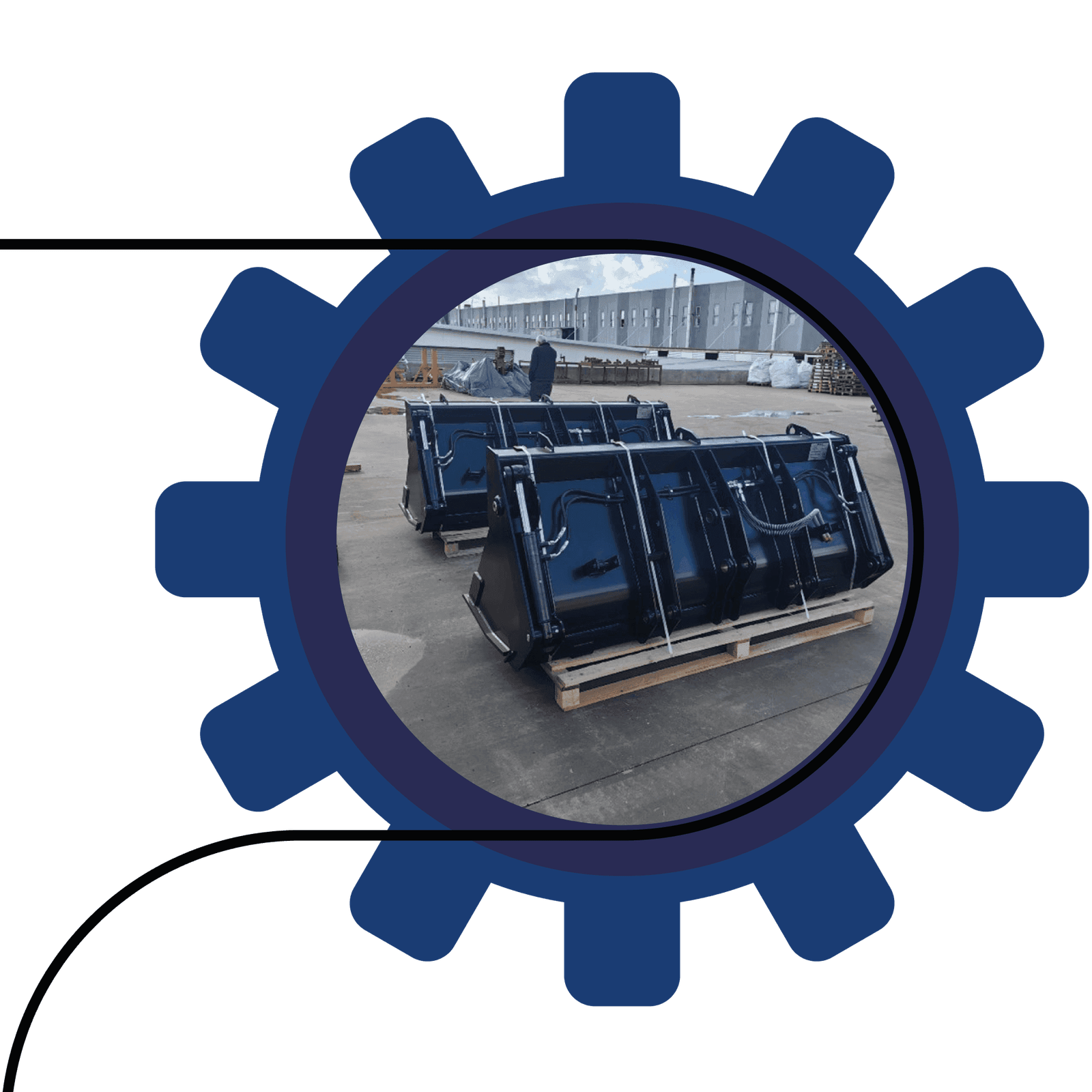

The fixtures, jigs, apparatus and jigs, which are designed and manufactured in accordance with the technical drawings and specifications of the product received from our customers, are meticulously measured and reported by our quality control team. Then, prototypes are produced on our production line. After the final control of the product, it is painted and packaged in accordance with customer demands and shipped with the PPAP file. This customer satisfaction-oriented process ensures that our products are produced in high quality and in accordance with expectations.

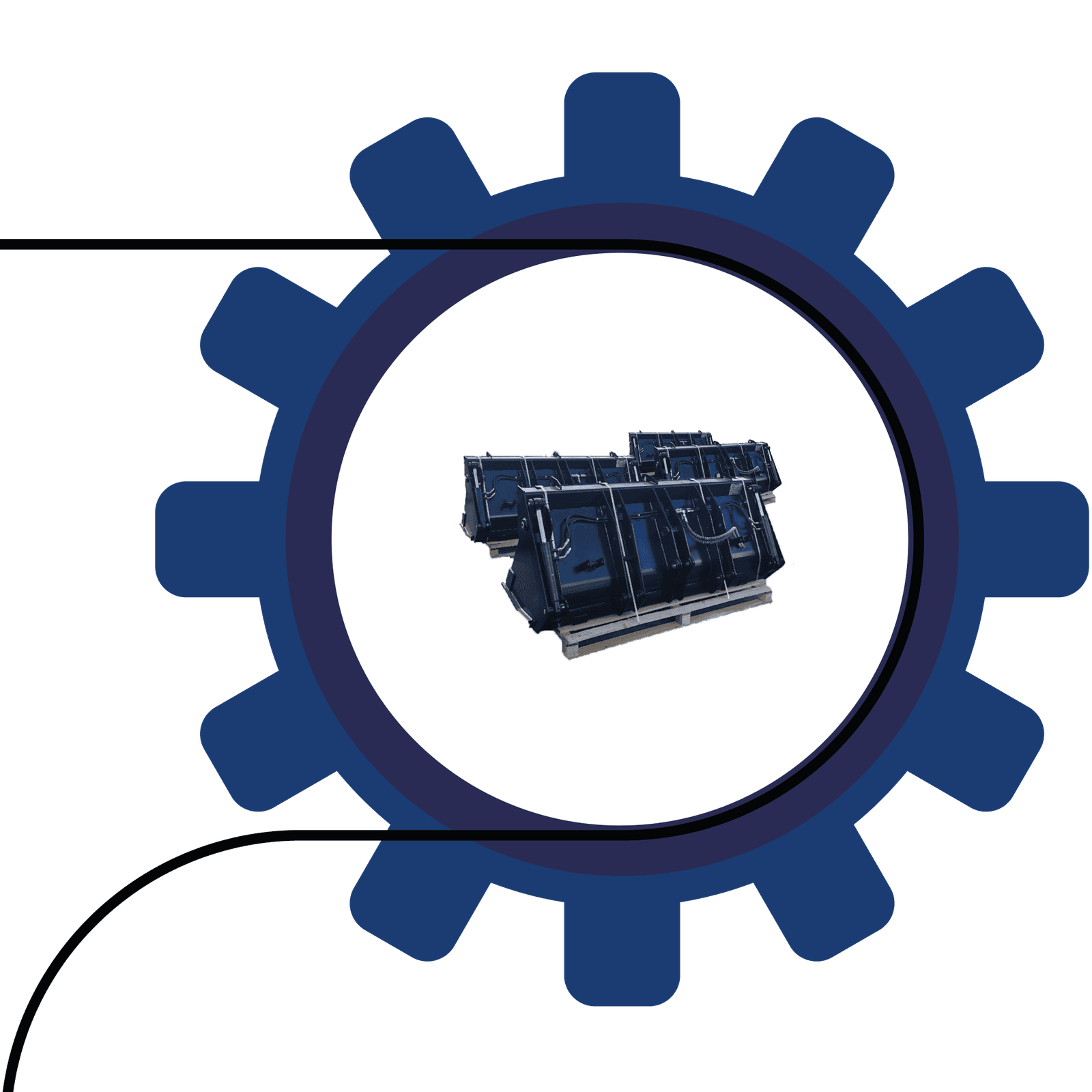

Hot Makina creates our weekly production plans flexibly and efficiently with an approach that focuses on the demands of our customers while determining the mass production quantities. Every part we produce is checked for compliance with customer technical drawings and specifications. After the loading organizations of the products are completed, they are carefully packaged and prepared for shipment in a way that best meets customer expectations and delivered quickly and safely around the world with reliable logistics networks.

Hot Makina meticulously considers the production capacity, machine capabilities and manufacturability analysis of the parts during the detailed evaluation process on your requests. Hot Makina aims to provide effective and cost-effective solutions in production processes, to establish long-term business relationships with our customers by committing to quality production and timely delivery by making detailed examinations of your proposal requests and projects.

Our design team uses the latest 2D and 3D design tools to bring fixture, jig, jig and gauge designs to life with a customized perspective. They also use advanced methods such as simulation and tolerance analysis to ensure that each part is manufactured with perfect fit and quality. This approach allows us to speed up our processes and create solutions tailored to our customers’ demands.

The fixtures, jigs, apparatus and jigs, which are designed and manufactured in accordance with the technical drawings and specifications of the product received from our customers, are meticulously measured and reported by our quality control team. Then, prototypes are produced on our production line. After the final control of the product, it is painted and packaged in accordance with customer demands and shipped with the PPAP file. This customer satisfaction-oriented process ensures that our products are produced in high quality and in accordance with expectations.

Hot Makina creates our weekly production plans flexibly and efficiently with an approach that focuses on the demands of our customers while determining the mass production quantities. Every part we produce is checked for compliance with customer technical drawings and specifications. After the loading organizations of the products are completed, they are carefully packaged and prepared for shipment in a way that best meets customer expectations and delivered quickly and safely around the world with reliable logistics networks.

Türkiye

France

England

Germany

Hot Makina was established on 02.07.2020 in Torbalı district of IZMIR. Our company, which operates on a total area of 4.450 m², has a closed area of 2.500 m².